Biostream

- Home

- We Represent

- Biostream

Biostream

Biostream International B.V. is a Dutch biotechnology company specializing in the design and manufacturing of bioreactors and fermentation equipment for various industries, including food, bio-based fermentation, algae cultivation, and cell culture. Founded in 2013 and headquartered in Doetinchem, Netherlands, the company has evolved from offering service and maintenance to providing a comprehensive range of standard and customized bioreactor solutions.

Biostream International B.V. offers a diverse range of bioreactor and fermentation systems tailored to various applications in biotechnology, food processing, and research. Their product portfolio includes:

Bioreactors and Fermenters

- Lab-Scale Bioreactors: Designed for research and development, these systems range from 50 ml to 15 liters. They feature precise control over parameters like pH, temperature, and dissolved oxygen.

- Pilot-Scale Fermenters: Suitable for scaling up processes, these fermenters offer volumes from 15 liters to several hundred liters, maintaining consistent control and monitoring capabilities.

- Production-Scale Systems: Customizable fermenters designed for industrial-scale production, with volumes up to 15 m³, incorporating features like Clean-In-Place (CIP) and Ultra-High Temperature (UHT) processing.

Specialized Equipment

- Photobioreactors: Tailored for algae cultivation, these systems include LED lighting control, gas mixing, and temperature regulation to optimize growth conditions.

- Cell Culture Bioreactors: Designed for mammalian and insect cell cultures, offering sterile environments with precise control over culture conditions.

- Custom Solutions: Biostream provides bespoke bioreactor systems to meet specific client requirements, integrating advanced monitoring and control technologies.

Models and features

Bio EZ. (‘Smart Simplicity for Serious Science’)

The Bio EZ is an entry-level bioreactor designed for “Smart Simplicity for Serious Science,” specifically purpose-built for straightforward and essential bioprocessing. It is intended to be a budget-friendly, low-CAPEX solution that empowers startups, researchers, and small producers to move projects from notebooks to experiments without the hurdles of high costs or steep learning curves

- Vessel and Volume: It features Autoclavable borosilicate jacketed /non jacketed glass vessel and 316 L stainless steel vessels. Users can easily switch between vessel sizes, with a working range from 0.2 L to 7.0 L depending on the vessel (0.75 L, 2 L, 5 L, or 7.5 L).

- Agitation: Equipped with a mechanical motor drive and two Rushton impellers, capable of speeds up to 1200 RPM.

- Aeration: Includes a standard Mass Flow Controller (MFC) for Air, with options to add MFCs for O2, N2, and CO2.

- Pumping: The console features four integrated peristaltic pumps with a range of 0.1–50 ml/min.

- Temperature Control: A range from 5°C above room temperature to 70°C, with a high-temperature range option for 80°C for short durations. An optional chiller can extend the range to 15°C below room temperature

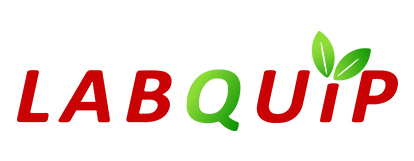

BioCompact (‘Parallel Power for Smarter Selection’)

The BioCompact is a bioreactor system described as providing “Parallel Power for Smarter Selection,” specifically designed for high-efficiency research and development workflows. Unlike the entry-level Bio EZ, the BioCompact is optimized for complex tasks such as strain optimization and parallel cultivation.

- Parallel Processing: Its primary focus is on parallel power, making it ideal for high-throughput applications.

- Stackable Design: The system is built to be stackable, allowing users to maximize laboratory space while operating multiple units.

- Volume Range: It supports Autoclavable borosilicate jacketed /non jacketed glass vessel with a working volume ranging from 0.25 L to 7.5 L.

- Customizability: It offers a high level of customizability through selected options to meet specific process requirements

BioBench (‘Limitless Configurations at Lab Scale‘)

Total Volume:2-13L;Microbial /CellCulture

The BioBench is Biostream’s highly versatile laboratory-scale bioreactor system, defined by its core philosophy of providing “Limitless Configurations at Lab Scale”. While the Bio EZ is an entry-level system and the BioCompact is optimized for parallel research, the BioBench serves as the high-customization workhorse for specialized applications.

- Most customizable unit in Benchtop Product Line

- Autoclavable Borosilicate jacketed and non-jacketed glass vessels

- Stainless steel vessels with Sterilizing in Place (SIP)

- Can be used with most of the single use vessels type available up to 13 L volume

- Working under pressure up to 6 Bars

BioBench Twin (‘Double Capacity and parallel production’)

Working volume: 2 L to 13 L;Glass;Cultivation of bacteria, algae, cells, and fungi

The BioBench Twin is a specific model designed for “Double Capacity” and “Parallel Production” while maintaining a clean design. It is categorized as having a medium customizability level compared to the standard BioBench but is purpose-built for users who require a dual reactor setup in a single system footprint.

- Most customizable unit in Benchtop Product Line

- Autoclavable Borosilicate jacketed and non-jacketed glass vessels

- Stainless steel vessels with Sterilizing in Place (SIP)

- Can be used with most of the single use vessels type available up to 13 L volume

- Working under pressure up to 6 Bars

BioTwin Pilot scale (‘Double Capacity, Clean Design’)

Working Volume: 15 L to 50 L;Stainless Steel

Compact Design controls 1 or 2 vessels.

Upgradable from a single-vessel to a dual-vessel configuration.

Stylish design which complies to all laboratory requirements, Possible upgrade from one vessel to a two vessel BioTwin.

15 “touch screen

BioTwin controller adopts a new PLC level touch screen design, and the detection sensor receives the signal transmission,

including 20 analog and 10 digital signal input channels such as temperature, stirring, pH, pO2, Redox, liquid level, gas flow,

pressure control, biomass, current and voltage standard signals. In addition, there are 12x analog signals, 24x digital signals

and, 32x Modbus for connecting drive and control expansion units, which can also be connected to monitoring software through OPC protocol.

Open water loop temperature control

Fully automatic cooling/heating/sterilization system.

BioPilot Large scale in situ sterilization and fermentation system

Working Volume: 3 L to 3000 L; Stainless Steel;Applications: Cultivation of bacteria, cells, algae, and fungi

Biostream can provide fermentation systems with a total reaction volume ranging from 3L to 3000L. With successful cases all over the world, Biostream is an ideal choice for your factory’s fermentation system.

Applicable types: bacteria, cells, algae, fungi culture.

It can be flexibly configured according to your laboratory space.

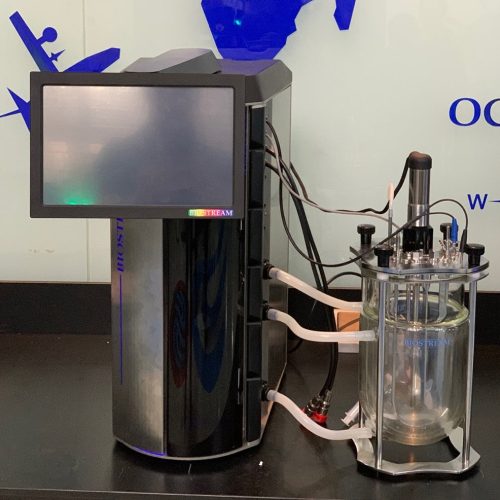

BOS 3.0

BOS 3.0 is more than just bioreactor control software: it’s your complete bioprocess companion. Built to support the next generation of fermentation, BOS 3.0 brings together process control, recipe automation, device integration, and data management in a single, intuitive platform. Whether you’re scaling up production or optimizing conditions in R&D, BOS 3.0 helps you stay in control.

What makes BOS 3.0 truly unique is its customer-centric design, developed in co-creation with users. Every feature is based on real-world feedback and tested to ensure maximum usability and relevance. We’ve built BOS 3.0 with your challenges in mind, empowering you to go further with less effort.

- Advanced Recipes: The software features a flexible, programmable engine that allows users to define multi-step sequences using conditional logic, loops, and complex dependencies. This supports high-end workflows such as adaptive feeding, ramping, and state-based transitions.

- Global Variables: BOS 3.0 introduces automatic synchronization between connected reactors. For example, a setpoint or batch ID defined for one reactor can be instantly shared with others, enabling system-wide coordination.

- Cascade Logic: The system supports standard PID cascade control as well as Advanced Cascade logic to stabilize complex processes.

- Modular Programs: Users can store and execute multiple configurations independently, such as sterilization or pasteurization protocols.

- Runtime Sterilization: A unique feature that allows the sterilization of transfer lines while a fermentation process is actively running.

Consistency and Seamless Scale-Up

- One Software, All Scales: The interface and logic are identical across all system sizes, from laboratory benchtop units to pilot and production-scale bioreactors.

- Linear Scale-Up: Process programs can be easily copied from one bioreactor to another, facilitating a smooth transition as production grows .

- Adaptive UI: The software activates only the options relevant to the specific bioreactor size being used, ensuring operators see exactly what they need for that unit.

Usability and Multimedia Integration

- Multimedia Integration: Users can embed videos, images, and documents (such as SOPs, training clips, or maintenance guides) directly into the UI alongside process controls.

- Multi-language Support: The interface supports multiple languages, which can be customized per individual user account.

- Preconfigured Device Templates: BOS 3.0 includes an expanded library of validated profiles for sensors and pumps, allowing for quick setup via Modbus and the logging of sensor lifetime or calibration data without external equipment.

- User Group Management: Administrators can create groups (e.g., technicians, researchers, production staff) with tailored access rights. For instance, a researcher might have the right to modify protocols, while an operator can only execute them.

- Network Communication: The software enables real-time data exchange between multiple bioreactors within a network, allowing systems to respond dynamically to one another.

- Smart Diagnostics: The software works with built-in PCB LED indicators to allow for remote troubleshooting.

- Remote Application Support: Experts can remotely review audit logs to provide guidance on automation strategies and result interpretation

FAQs

A bioreactor is a vessel that supports controlled biological reactions for producing bio-products like pharmaceuticals and biofuels.

Bioreactors offer better control over the production environment, improving the consistency and quality of the product. They enhance yield, reduce contamination risks, and allow for scalable production in industries like biotechnology, agriculture, and pharmaceuticals.

we have 5 types include BioCompact Multiple Reactor, BioBench Twin, BioBench, BioProject and BioPilot, each suited for different production needs.

Labquip Asia offers tailored bioreactor systems, providing expert guidance and solutions for efficient biological production, ensuring high performance and reliability for various industrial applications.

They support microbial and cell growth by controlling pH, oxygen, temperature, and nutrients.

Fermenters range from small lab-scale (50 ml) to large production-scale systems (up to 15 m³).

They are widely used in pharmaceuticals, biotech, food, beverages, and agriculture.

Most systems include Clean-in-Place (CIP) features for easy cleaning and sterilization.